Cast Steel Trunnion Mounted Ball Valve

1. Product overview

A typical cast steel trunnion mounted ball valve, worm gear operated, RF flanged ends, 2 piece split body, full port, 6″ 600LB.

Metals Valve provides cast steel trunnion mounted ball valves in a wide variety of cast materials covering carbon steel, alloy steel, and stainless steel. The ball of a trunnion mounted ball valve is fixed or constrained at two pivot points(upper stem and bottom stem). Buy using a bearing at the bottom stem(trunnion), only pivoting movement is allowed within the body cavity. The upstream seat is a floating seat and the process pressure pushes it against the ball’s sealing surface. The seat can also be pre-stressed during assembly, using seats that have a spring action. This design applies continuous pressure against a trunnion-mounted ball after the ball is installed, while the top-works apply a load to the entire closure member. Cast steel trunnion mounted ball valves are often soft seated and can attain a bubble tight sealing.

2. Design features and material selection

Design standards: API 6D, API 608, BS 5351, ISO 14313, ASME B16.34; Fire safe to API 607, BS 5146, ISO 10497; End connection: ASME B16.5, ASME B16.25, ASME B16.11; Face to face: ASME B16.10; Inspection and test: API 598, API 6D, EN 12266-1. The cast steel trunnion mounted ball valve is available in either full port(FB) or reduced port(RB), 2 piece split body, lever/gear or actuator operated.

| Cast Steel Trunnion Mounted Ball Valve, 2 Piece Split Body, Side Entry - Table Chart | ||||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

Design Features

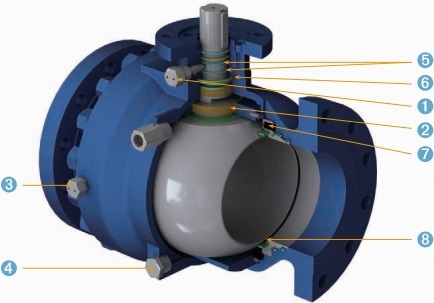

Illustration of design features of a conventional cast steel trunnion mounted ball valve, 2 piece split body with ISO mounting pad.

(1) The stem sealant injection fitting is furnished to prevent leakage from the stem in case of emergency.

(2) T-shaped blow-out proof stem design.

(3) The seat sealant injection fitting is furnished to prevent leakage from the seat.

(4) Bleeding/ venting plug to drain the body cavity to avoid over pressure.

(5) Double sealing O-rings to prevent leakage from stem area.

(6) Gasket & O-ring arrangement to prevent leakage from body joint.

(7) Seat spring to exert force on the seat to ensure a tight sealing even at low line pressure.

(8) Fire safe design: in case soft seating materials are deteriorated after fire, metal to metal sealing is available.

Material Selection

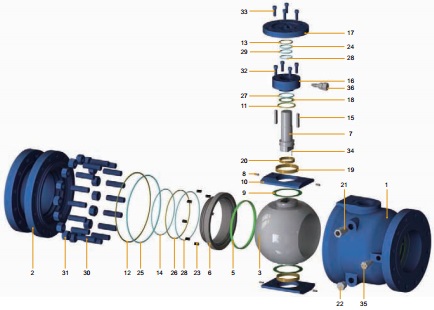

The 3D explosive view of a cast steel trunnion mounted ball valve, 2 piece split body.

| ITEM | PART NAME | STANDARD MATERIAL | STAINLESS STEEL | LOW-TEMP SERVICE |

|---|---|---|---|---|

| 1 | Body | ASTM A216 WCB | ASTM A351 CF8M | ASTM A352 LCB |

| 2 | Bonnet | ASTM A216 WCB | ASTM A351 CF8M | ASTM A352 LCB |

| 3 | Ball | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 4 | Seat | see 5&6 | see 5&6 | see 5&6 |

| 5 | Seat Insert | RPTFE/PEEK/NYLON | RPTFE/PEEK/NYLON | RPTFE/PEEK/NYLON |

| 6 | Seat Ring | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 7 | Stem | ASTM A105N+ENP | ASTM A182 F316 | ASTM A350 LF2+ENP |

| 8 | Alignment Pin | Stainless Steel | Stainless Steel | Stainless Steel |

| 9 | Thrust Washer | PTFE | PTFE | PTFE |

| 10 | Support | ASTM A588 B+ENP | ASTM A351 CF8M | ASTM A588 B+ENP |

| 11 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 12 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 13 | Seal Ring | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 14 | Seal Ring | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 15 | Key | Carbon Steel | Carbon Steel | Carbon Steel |

| 16 | Cover Flange | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 17 | Top Flange | ASTM A105N | ASTM A182 F316 | ASTM A350 LF2 |

| 18 | Thrust Washer | PTFE | PTFE | PTFE |

| 19 | Bearing | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 |

| 20 | Bearing | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE |

| 21 | Vent Valve | Stainless Steel | Stainless Steel | Stainless Steel |

| 22 | Drain Plug | Stainless Steel | Stainless Steel | Stainless Steel |

| 23 | Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 24 | O-Ring | NBR | NBR | NBR |

| 25 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 26 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 27 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 28 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 29 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 30 | Body Stud | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 31 | Body Nut | ASTM A194 2H | ASTM A194 8 | ASTM A194 7M |

| 32 | Screw | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 33 | Screw | ASTM A193 B7 | ASTM A193 B8 | ASTM A320 L7M |

| 34 | Anti-Static | SS304/SS316 | SS304/SS316 | SS304/SS316 |

| 35 | Injection | SS304/SS316 | SS304/SS316 | SS304/SS316 |

| 36 | Injection | SS304/SS316 | SS304/SS316 | SS304/SS316 |