Material & Actuator Selection for V Port Ball Valves

1. Material selection of V port ball valves

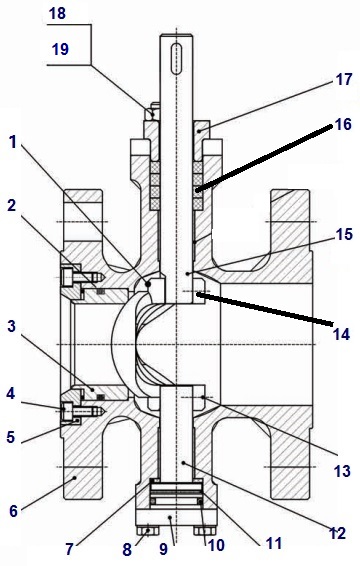

Technical Drawing

Technical G.A drawing of a V port ball valve, trunnion mounted with RF flange ends.

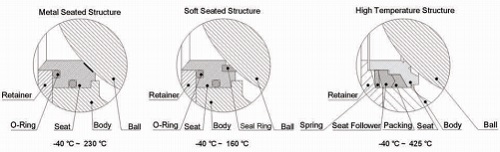

Seating designs for V port ball vlve: metal seated, soft seated, high-temp. structure.

See more specifications of trunnion mounted V port ball valves. Also see the dimensional data sheets for RF flanged type and wafer type respectively.

Material Specification

| Item No. | Part Name |

|---|---|

| 1 | Ball |

| 2 | O-Ring |

| 3 | Seat |

| 4 | Screw |

| 5 | Retainer |

| 6 | Body |

| 7 | Gasket |

| 8 | Bolt |

| 9 | Bottom Cap |

| 10 | O-Ring |

| 11 | Gasket |

| 12 | Bottom Stem |

| 13 | Bearing |

| 14 | Bearing |

| 15 | Upper Stem |

| 16 | Stem Packing |

| 17 | Gland Flange |

| 18 | Bolt |

| 19 | Nut |

| Part Name | Material |

|---|---|

| Body | ASTM A216 WCB, ASTM A217 WC6, ASTM A351 CF8/ CF8M |

| Stem | ASTM A182 F304/ F316 |

| Retainer | ASTM A351 CF8/ CF8M |

| Seat | PTFE, SS304, SS316, SS316+STL, SS316+Cr |

| Packing | PTFE, Graphite |

| O-Ring | NBR, Fluorin Rubber |

2. Flow characteristics and actuator selection

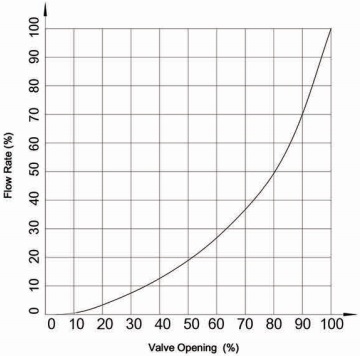

Flow Characteristics

The flow characteristic curve of V port ball valves: Equal Percentage.

| Flow Coefficient Cv | ||||||||||||||

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| Cv | 27 | 47 | 70 | 110 | 170 | 280 | 410 | 750 | 980 | 1720 | 2900 | 3800 | 7000 | 9800 |

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| Soft Seated | 6.4 | 6.4 | 6.0 | 4.8 | 3.2 | 3.0 | 2.4 | 1.2 | 1.3 | 1.1 | 0.9 | 0.6 |

| Metal Seated | 6.0 | 5.8 | 4.2 | 3.7 | 2.4 | 2.3 | 1.4 | 1.2 | 0.9 | 0.8 | 0.7 | 0.4 |

Pneumatic Actuator

A wafer type V port ball control valve, 150LB 6″, trunnion mounted with pneumatic actuator.

| Function | Angle-travel for throttling or on-off services. |

| Structure | Pneumatic Cylinder Type, Spring Return Type(Double Acting) |

| Actuator Type | Direct Action, Reverse Action. |

| Air Supply | 0.6 MPa(G) |

| Connection | Rc 1/4" |

| Action | Direction action: air to valve shut; Reverse action: air to valve open. |

| Intrinsic Error | ±2%(with positioner), ±5%(without positioner) |

| Hysteresis | 1%(with positioner); 5%(without positioner) |

| Hysteresis Erro | 1%(with positioner); 3%(without positioner) |

| Ambient Temp. | -20~80℃ |

| Accessaries | E/P, P/P-Positioner; Air-Set; Solenoid Valve; Limit Switch, etc. |

| Double Acting | PAD075 | PAD092 | PAD105 | PAD125 | PAD140 | PAD160 | PAD190 | PAD210 | PAD270 |

| Torque(N*m) | 60.4 | 136.3 | 197.3 | 308 | 526 | 802 | 1292 | 1579 | 2463 |

| Single Acting | PAS091 | PAS125 | PAS140 | PAS190 | PAS210 | PAS240 | PAS270 | PAS300 | PAS400 |

| Torque(N*m) | 71.2 | 159.5 | 281.7 | 706 | 860 | 1270 | 2033 | 2563 | 3026 |

Electric Actuator

A wafer type V port ball control valve, electric actuator operated, 4″ 300LB.

| Function | Electric actuators for throttling and on-off applications. |

| Structure | Solid State Electric Type |

| Power Voltage | 220 VAC |

| Resolution | ±1% |

| Hysteresis | 2% FS |

| Ambient Temperature | -20~80℃ |

| Optional Accessories | Torque Switch, Space Heater, Junction Box, Potentiometer, etc. |

| Actuator Type | EA010 | EA020 | EA040 | EA060 | EA100 | EA150 | EA200 | EA250 |

| Torque(N*m) | 100 | 200 | 400 | 600 | 1000 | 1500 | 2000 | 2500 |

| Travel Angle | 0~90° | 0~90° | 0~90° | 0~90° | 0~90° | 0~90° | 0~90° | 0~90° |

| Acting time(s) | 30 | 30 | 30 | 30 | 30 | 45 | 60 | 75 |

Actuator Selection

| DN | Pneumatic Actuator | Electric Actuator | |

| Double Acting | Single Acting | ||

| 25 | PAD075 | PAS091 | EA010 |

| 32 | PAD075 | PAS091 | EA010 |

| 40 | PAD092 | PAS125 | EA010 |

| 50 | PAD092 | PAS125 | EA010 |

| 65 | PAD092 | PAS125 | EA010 |

| 80 | PAD105 | PAS140 | EA020 |

| 100 | PAD105 | PAS140 | EA020 |

| 125 | PAD125 | PAS140 | EA040 |

| 150 | PAD140 | PAS192 | EA060 |

| 200 | PAD160 | PAS200 | EA100 |

| 250 | PAD190 | PAS240 | EA150 |

| 300 | PAD210 | PAS270 | EA200 |

| 350 | PAD270 | PAS270 | EA250 |

| 400 | PAD270 | PAS270 | EA250 |

CATEGORY AND TAGS: